The rapid rise of electric vehicles (EVs) has brought batteries to the forefront of automotive technology, with a particular focus on achieving advancements in energy efficiency, longevity, and safety. Batteries are not just a component but a critical factor in defining the performance, reliability, and sustainability of EVs. This shift in focus has led to extensive research and development across multiple types of lithium-ion battery chemistries to meet the evolving demands of EV consumers and the stringent requirements of modern vehicles. From enhancing driving range to ensuring thermal stability and reducing environmental impact, batteries play an essential role in shaping the future of electric mobility. Given the wide variety of EVs on the market, battery choice is influenced by several factors, including performance requirements, cost considerations, safety profiles, and environmental sustainability goals.

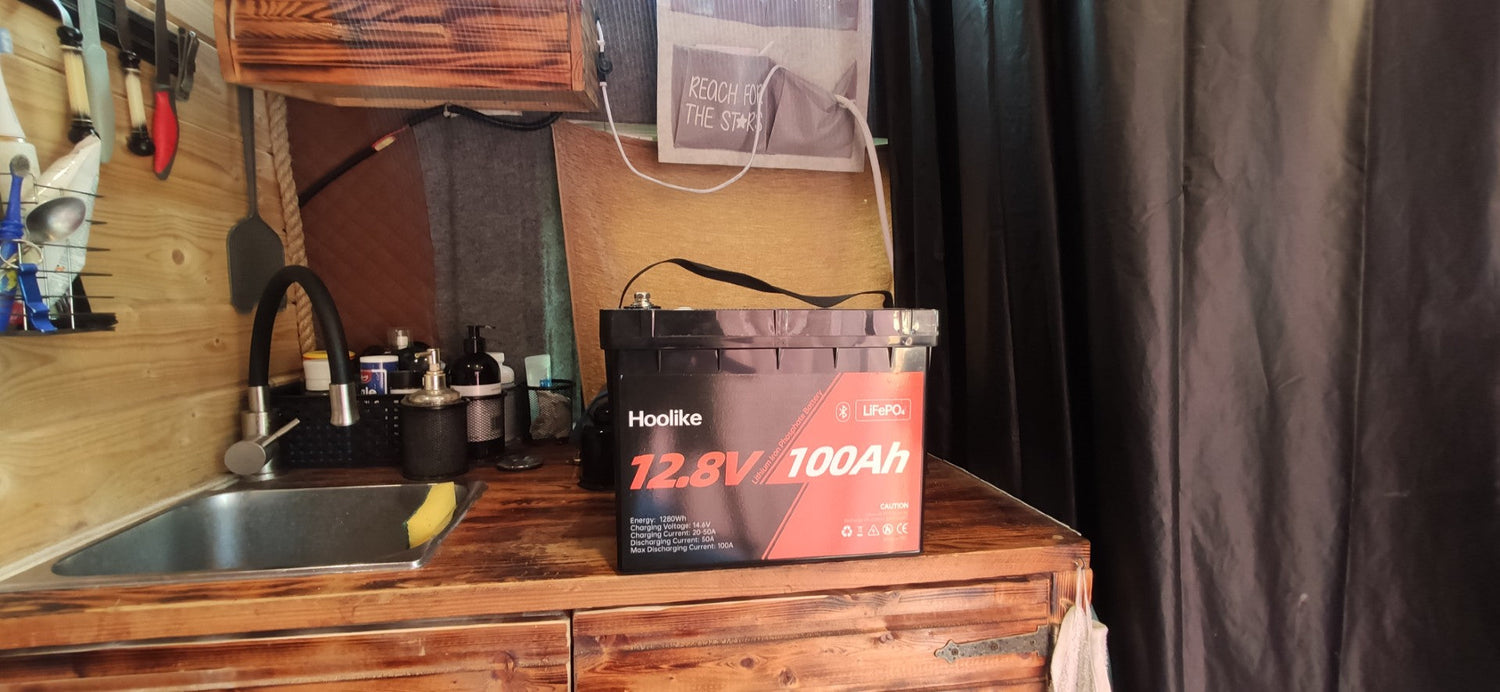

While several battery types are currently used in the EV market, LiFePO4 (Lithium Iron Phosphate) batteries have gained significant popularity, especially among manufacturers seeking a reliable and sustainable solution. LiFePO4 batteries offer a unique blend of performance benefits, environmental advantages, and cost-effectiveness, making them well-suited for specific applications within the EV sector. Unlike some other lithium-ion chemistries, LiFePO4 batteries are known for their high cycle life, stability, and thermal runaway resistance, enhancing their safety profile. These features make LiFePO4 batteries an attractive choice for EV models designed for durability and consistent performance over time. Additionally, as sustainability becomes a priority, the environmental benefits of LiFePO4, such as reduced reliance on scarce minerals like cobalt, align well with the automotive industry's goals of minimizing ecological impact. This article will explore the specific advantages of LiFePO4 batteries in EV applications and examine how they compare to other popular lithium-ion chemistries, such as Nickel Manganese Cobalt (NMC) batteries, which are commonly found in high-performance models like the Tesla Model 3 and Ford Mustang Mach-E. Through this comparison, we can better understand why LiFePO4 is emerging as a preferred choice for sustainable electric mobility.

Understanding LiFePO4 Batteries in the EV Landscape

LiFePO4 batteries, a subtype of lithium-ion batteries, are renowned for their remarkable cycle life, stability, and resistance to thermal runaway, which collectively enhance their suitability for electric vehicle (EV) applications. These batteries, also known as lithium iron phosphate (LFP), stand out as a safer and more durable solution than other lithium-ion chemistries. While lithium batteries like Nickel Manganese Cobalt (NMC) or lithium cobalt often feature higher energy densities, which translate to longer ranges in EVs, they come with drawbacks in terms of stability and susceptibility to overheating. LiFePO4 batteries, though slightly lower in energy density, make up for this by providing excellent thermal stability and robustness in varying temperatures. This resilience in different climates makes LFP batteries an ideal choice for EV applications, especially in regions with temperature fluctuations, where other chemistries may be more prone to degradation or performance loss.

The advantages of LiFePO4 batteries become even more apparent when considering the supply chains and environmental impact associated with different battery chemistries. Traditional lithium-ion batteries, such as NMC batteries, heavily rely on materials like nickel and cobalt, which are scarce and have significant environmental and ethical concerns. Mining cobalt, in particular, has been associated with challenging working conditions, human rights issues, and ecological degradation in regions where it is primarily sourced. LiFePO4 batteries, by contrast, are manufactured using lithium iron phosphate, composed of more widely available and less controversial materials. This reduces dependency on high-impact resources, creating a more sustainable supply chain and lowering the environmental footprint associated with battery production.

Furthermore, the reliance on more abundant and ethically sourced materials gives LiFePO4 batteries a notable edge in sustainability, which is becoming an increasingly important factor in the EV industry. With a focus on reducing environmental impact, manufacturers and consumers seek products that align with eco-friendly practices. The reduced ecological strain in LiFePO4 battery production not only enhances the appeal of these batteries for environmentally conscious consumers but also supports the long-term sustainability goals of automakers. This shift towards LiFePO4 technology responds to consumer demand for greener products and the automotive industry’s commitment to developing sustainable energy solutions. By minimizing reliance on scarce resources and avoiding ethically problematic materials, LiFePO4 batteries contribute to a cleaner, more responsible approach to battery manufacturing, making them a promising alternative toward sustainable electric mobility.

LiFePO4 vs. NMC: Comparing Battery Performance in EVs

One of the most common lithium-ion battery chemistries in high-performance electric vehicles (EVs) is the Nickel Manganese Cobalt (NMC) battery. Known for its high energy density, NMC batteries are commonly found in popular EV models like the Tesla Model S and Ford Mustang Mach-E. This high energy density translates into extended driving ranges and robust performance, allowing these vehicles to meet the demands of consumers who prioritize long distances between charges and powerful acceleration capabilities. As a result, NMC batteries have become a preferred choice for EVs aiming to maximize range and performance metrics. However, while these batteries are exceptional in energy storage, their use does come with certain drawbacks, particularly regarding safety, longevity, and environmental concerns.

One significant issue associated with NMC and similar lithium-ion chemistries, such as lithium cobalt batteries, is the risk of thermal runaway. Thermal runaway is a phenomenon where the battery can overheat to the point of combustion or even explosion, especially under extreme conditions like high temperatures, rapid charging, or physical damage. This vulnerability makes NMC batteries more susceptible to overheating and potential safety hazards, which can be concerning in high-demand scenarios. These safety concerns become more pronounced as EVs become more integrated into everyday life, including in high-temperature climates or with extensive daily use. In contrast, LiFePO4 (Lithium Iron Phosphate) batteries offer substantial resistance to thermal runaway. Their stable chemical structure significantly reduces the risk of overheating, making them a safer option for EV applications, particularly in scenarios involving frequent charging cycles, high temperatures, or strenuous driving conditions that can strain battery safety.

Another advantage of LiFePO4 batteries is their durability and extended cycle life compared to NMC batteries. Cycle life refers to the number of charge-discharge cycles a battery can undergo before its capacity significantly deteriorates. While NMC batteries provide impressive energy density, they tend to have a shorter cycle life, meaning their performance degrades faster with repeated charging and discharging. LiFePO4 batteries, on the other hand, can endure thousands of cycles with minimal capacity loss. This long cycle life makes LiFePO4 batteries especially appealing for EVs, prioritizing longevity and consistent performance over extended driving ranges. This durability means fewer replacements are necessary over the vehicle’s lifespan, reducing costs for EV owners and supporting a lower environmental impact by decreasing the need for frequent battery production, which involves resource-intensive manufacturing processes.

The cost-effectiveness and environmental benefits of LiFePO4 batteries contribute to their appeal for specific EV applications. While NMC batteries are well-suited for high-performance models prioritizing range and power, LiFePO4 batteries cater to EV models that value reliability, affordability, and sustainability. For instance, family-oriented or city-focused EVs, where extreme performance is less critical, benefit from the stability and longevity that LiFePO4 batteries provide. Moreover, requiring fewer replacements over the vehicle's lifespan, LFP batteries reduce the environmental burden associated with battery production and disposal. This aligns with broader sustainability goals in the automotive industry, as LiFePO4 batteries contribute to lowering the lifecycle impact of EVs. In the long term, LiFePO4 batteries represent a cost-effective and environmentally conscious choice for consumers and manufacturers alike, meeting the needs of those who prioritize safety, durability, and ecological responsibility in their vehicle's power source.

Cold Weather Performance: LiFePO4 Batteries in Low Temperatures

Battery performance in cold weather is crucial for EV owners, especially in regions with harsh winters where low temperatures can significantly impact a vehicle's reliability and usability. Batteries are known to lose efficiency and capacity when exposed to extreme cold, affecting an EV's range and the overall driving experience. This is particularly concerning for electric vehicle users who need dependable performance throughout all seasons, including winter. NMC (Nickel Manganese Cobalt) batteries, one of EVs' most widely used lithium-ion chemistries, generally perform well in moderate conditions. However, they can still suffer from reduced efficiency in extremely low temperatures. When temperatures drop, the internal resistance of these batteries increases, leading to a reduction in energy output and a decrease in charging speeds. This makes it difficult for drivers in colder climates to rely solely on NMC batteries without considering additional thermal management systems or alternative battery chemistries that handle temperature fluctuations better.

LiFePO4 (Lithium Iron Phosphate) batteries, while recognized for their stability, safety, and long cycle life, are also susceptible to performance issues in cold weather. Cold temperatures can slow the chemical reactions within LiFePO4 cells, reducing their ability to deliver power effectively. This can impact the acceleration and range of electric vehicles relying on LFP batteries in winter conditions. However, the effects of cold weather on LiFePO4 batteries tend to be less pronounced than other battery types due to their inherent thermal stability. Despite this advantage, cold weather does present challenges for LFP battery performance. With intervention, these batteries may be able to meet the needs of drivers in regions where temperatures regularly fall below freezing. The implications of these limitations have prompted manufacturers and researchers to explore solutions that enhance the resilience of LiFePO4 batteries in low temperatures.

Fortunately, recent advancements in Battery Management Systems (BMS) are helping to mitigate cold weather issues for both NMC and LiFePO4 batteries. A BMS is an electronic system that monitors and manages various aspects of battery performance, including temperature, voltage, and current. For LiFePO4 batteries, improved thermal management through sophisticated BMS technology is an effective solution for maintaining consistent performance in cold conditions. Modern BMS units can regulate the temperature of the battery cells by actively heating them when the vehicle is turned on or charging. This ensures the battery operates within an optimal temperature range, even in freezing climates, allowing the car to deliver reliable power output and charge reasonably. Such advancements in BMS technology make using LiFePO4 batteries in a broader range of environments feasible, expanding their applicability in electric vehicles across various geographic regions.

With these thermal management and battery technology improvements, LiFePO4 batteries are becoming more resilient to temperature variations, further enhancing their suitability for electric vehicles. As these innovations continue to develop, LFP batteries may emerge as a preferred choice in colder climates, where their stability and resistance to thermal runaway offer distinct safety advantages over other battery chemistries. This makes them an attractive option for EV manufacturers seeking to build efficient but also reliable and safe vehicles across all weather conditions. For drivers, the enhanced cold-weather performance of LiFePO4 batteries means greater peace of mind, as they can rely on their cars even during the harshest winter months. As the EV industry moves toward sustainable and versatile battery solutions, LiFePO4 batteries, with the support of advanced BMS systems, are well-positioned to meet the demands of a growing, climate-diverse consumer base.

A Sustainable Choice: The Environmental Impact of LiFePO4 Batteries

From an environmental perspective, LiFePO4 (Lithium Iron Phosphate) batteries offer a significant advantage over other commonly used battery chemistries in electric vehicles, such as Nickel, Manganese Cobalt (NMC), and cobalt-based batteries. One of the leading environmental benefits of LiFePO4 batteries lies in their material composition, which excludes cobalt and requires minimal nickel. Cobalt mining, in particular, has long been associated with severe environmental degradation and ethical issues, including poor labor practices and exploitation in certain mining regions. This has led to growing concern about cobalt-dependent batteries' sustainability and human rights impacts. By relying on more abundant and less controversial materials, LiFePO4 batteries reduce mining-related environmental damage, helping to alleviate the adverse social and ecological effects commonly associated with traditional lithium-ion batteries.

The environmental benefits of LiFePO4 batteries extend beyond simply reducing the need for controversial raw materials. The production process for LFP batteries is generally less resource-intensive than cobalt-based batteries, leading to a smaller overall environmental footprint. Mining nickel and cobalt disrupts ecosystems, generates substantial greenhouse gas emissions, and consumes large amounts of water and energy. By minimizing the reliance on these materials, LiFePO4 batteries lessen the strain on critical resources, making them a more sustainable choice for raw material consumption. This reduced environmental footprint is precious in the context of electric vehicles, where the goal is to reduce tailpipe emissions and minimize the ecological impact of the entire vehicle lifecycle, including production and disposal.

Tesla, one of the leaders in the electric vehicle industry, has recognized the sustainability advantages of LiFePO4 batteries and has begun incorporating them into some of its EV models. Tesla has opted to use LFP batteries as a more environmentally responsible alternative to NMC for its standard-range versions in specific markets. This shift reflects a broader trend within the automotive industry, as manufacturers increasingly prioritize sustainable practices and look for ways to reduce the ecological impact of their products. While LiFePO4 batteries may require larger battery packs to achieve the same range as high-density NMC batteries, the environmental benefits of reducing reliance on problematic resources like cobalt make this a worthwhile trade-off for many automakers. By choosing LiFePO4, Tesla and other companies are signaling a commitment to sustainable battery technology that aligns with their mission to reduce environmental impact.

As the global demand for electric vehicles continues to grow, the importance of sustainable battery choices becomes more critical. LiFePO4 batteries offer a promising solution for manufacturers and consumers concerned about their energy sources' environmental and ethical implications. By choosing batteries with fewer controversial materials, EV manufacturers can contribute to a more sustainable supply chain and help shift the industry away from resources associated with deforestation, water pollution, and exploitative labor practices. The adoption of LiFePO4 batteries also supports a circular economy approach, as these batteries are more recyclable than traditional lithium-ion chemistries, further contributing to sustainability in the long term. With the automotive industry increasingly adopting green practices, LiFePO4 batteries represent a step toward cleaner, more responsible energy storage solutions that meet the growing demand for eco-friendly transportation options.

The Future of LiFePO4 in Electric Vehicles

As electric vehicle technology advances, the role of LiFePO4 (Lithium Iron Phosphate) batteries in the EV market is expected to expand significantly. With major automakers such as Tesla and BYD increasingly investing in LFP technology, the industry is poised to offer consumers more affordable, durable, and safer battery options in the coming years. This investment in LiFePO4 signals a shift in focus toward more sustainable energy storage solutions and reflects a recognition of the broader advantages LFP batteries provide, particularly for everyday EV applications. Unlike other lithium-ion chemistries, LiFePO4 batteries offer a long cycle life and a stable performance profile, making them highly suitable for electric vehicles, prioritizing reliability and lifespan over extreme performance. As more companies incorporate LFP batteries into their standard-range models, the affordability of EVs is likely to improve, making them accessible to a broader range of consumers and supporting the global shift towards cleaner transportation options.

The benefits of LiFePO4’s longer cycle life, stable performance, and environmentally friendly composition position it as a strong contender for diverse EV applications, from city commuters to family-oriented vehicles. Although LiFePO4 batteries do not possess the same energy density as Nickel Manganese Cobalt (NMC) batteries, their superior cycle life, safety profile, and reduced reliance on scarce and ethically problematic resources make them particularly appealing for sustainable and morally responsible EV production. This composition also aligns with the industry's increasing commitment to reducing ecological impact and supporting responsible supply chains. By focusing on durability and lower environmental costs, LiFePO4 batteries provide an ideal solution for applications where high-performance metrics like top speed and extended range aren’t the primary focus, allowing them to thrive in more practical, everyday electric vehicle models that prioritize longevity and safety.

In summary, while LiFePO4 batteries may not match the energy density of NMC batteries typically found in high-performance EV models, their unique combination of safety, longevity, and sustainable sourcing makes them a crucial component in the future of electric vehicles. As battery technology evolves, LiFePO4 batteries will play an increasingly vital role in supporting the global transition to greener transportation solutions. The industry-wide shift toward lithium iron phosphate could significantly reshape the electric vehicle landscape by making EVs more affordable and environmentally friendly for future generations. In this way, the rise of LiFePO4 batteries aligns with a broader movement towards sustainability, helping redefine what is possible for both EV performance and eco-conscious manufacturing in the coming years.